Wireless Infrastructure

As healthcare demands continue to grow, effective sterilization and waste management solutions become ever more critical. Microwave heating technologies have emerged as a highly effective tool in the sterilization of medical equipment and the inactivation of biohazardous waste. Compared to conventional methods such as ultraviolet (UV) sterilization, autoclaving, and chemical treatments, microwave heating offers faster, more energy-efficient, and environmentally friendly solutions for sterilization. In this article, we explore the benefits of microwave heating for sterilization, how it can be applied to both medical instruments and medical waste, and why RFHIC’s GaN-based microwave technology is setting new standards for the healthcare industry.

Microwave Heating in Sterilization Equipment

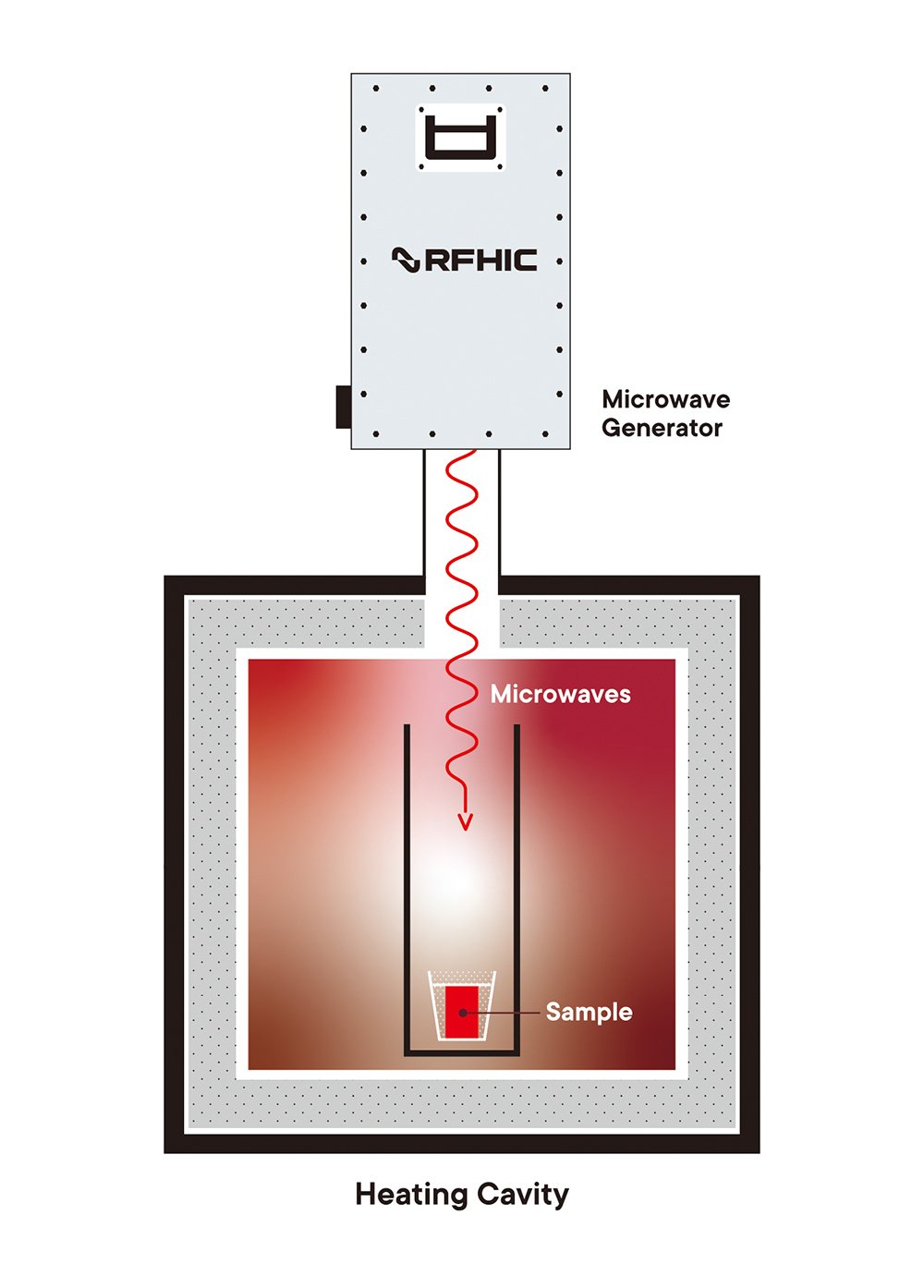

Microwave heating is based on the generation of electromagnetic waves that cause water molecules in the target material to oscillate, generating heat through friction. This heating process is highly effective for destroying microorganisms such as bacteria, viruses, and spores. Microwave sterilization is not only effective for medical equipment but also offers advantages for sterilizing complex, porous, and sensitive materials that are more difficult to treat with traditional methods like autoclaving or UV light.

Microwave technology operates on a wide frequency spectrum (typically around 2450 MHz) and delivers heat directly to the materials being treated, leading to faster and more efficient sterilization. This makes it particularly suitable for medical environments where rapid and reliable sterilization is essential.

Benefits of Microwave Sterilization Compared to Conventional Methods

1. Faster Sterilization: Unlike autoclaving, which relies on high-pressure steam, microwave heating can sterilize equipment within minutes. Autoclaving can take over an hour, making microwave heating a more efficient choice for high-demand environments.

2. Energy Efficiency: Microwave sterilization consumes significantly less energy compared to autoclaves and UV systems. The direct heating process in microwaves means less energy is lost, reducing overall energy consumption and operational costs.

3. Material Compatibility: Many medical devices made from plastics or electronics can be damaged by the high temperatures used in autoclaving. Microwave heating operates at lower temperatures, making it safe for heat-sensitive materials without compromising sterilization efficacy.

4. Deeper Penetration: While UV light only sterilizes surface-level microorganisms, microwave energy penetrates deeper, ensuring complete sterilization of complex and porous materials.

5. No Harmful Residue: Microwave sterilization eliminates the need for chemicals, leaving no toxic residues behind, which makes it safer for sensitive medical applications and the environment.

Microwave Sterilization for Medical Waste Management

In addition to sterilizing medical instruments, microwave technology is also used for the safe and effective inactivation of biohazardous waste, including medical waste like contaminated dressings, syringes, and even sewage sludge. In many developing countries, inappropriate treatment and disposal of biohazardous waste pose serious health and environmental risks. Microwave sterilization can be employed to treat medical waste on-site, minimizing transport risks and reducing the carbon footprint associated with incineration or chemical treatments.

Microwave irradiation has proven effective in treating a wide variety of biohazardous materials, including healthcare waste and sewage sludge. The technology is particularly effective for inactivating pathogens in waste materials that contain sufficient moisture, which makes it a valuable tool for hospitals, clinics, and developing countries where waste management infrastructure may be inadequate.

Key Benefits for Medical Waste Sterilization:

RFHIC’s GaN-Based Microwave Solutions for Sterilization

RFHIC offers a range of state-of-the-art GaN (Gallium Nitride) microwave generators that are ideal for sterilization applications. GaN technology provides higher power density and greater efficiency than conventional heating technologies, ensuring superior performance for both medical sterilization and waste management.

COTS Product Portfolio

Low Power Microwave Generators for Small Scale Sterilization Equipment

|

Product Name |

Frequency (MHz) | Output Power (W) | Cooling Type | Efficiency (%) |

| RIM25100-20G | 2400~2500 | 1~100 | External Heat sink & airflow | 60 |

| RIM25200-20G | 2400~2500 | 1~200 | External Heat sink & airflow | 60 |

| RIM25300-20G | 2400~2500 | 10~300 | External Heat sink & airflow | 60 |

| RIM25500-20G | 2400~2500 | 10~500 | Water cooled | 60 |

| RIM251K6-20G | 2400~2500 | 100~1600 | Water cooled | 57 |

High Power Microwave Generators for Large Scale Medical Waste Sterilization Equipment

These high-power microwave generators are complete turn-key solutions that include SSPAs, high-switch mode power supply units, cables, and Windows GUI control software. RFHIC’s turn-key systems are designed for easy integration, allowing users to simply plug them in and set them up with their existing systems.

|

Product Name |

Frequency (MHz) | Output Power (W) | Cooling Type | Efficiency (%) |

| RIU243K0-40TG | 2400-2500 | 30-3000 | De-ionized water | 58 |

| RIU093K0-40TG | 900-930 | 30-3000 | De-ionized water | 65 |

| RIU256K0-40TG | 2400-2500 | 300-6000 | De-ionized water | 58 |

| RIK2512K-40TG_H | 2400-2500 | 600-12000 | De-ionized water | 54 |

| RIK0915K-40TG | 900-930 | 1000-15000 | De-ionized water | 65 |

| RIK2524K-40TG | 2400-2500 | 600-24000 | De-ionized water | 51 |

| RIK0930K-40TG | 900-930 | 1000-30000 | De-ionized water | 65 |

| RIK0960K0-40TDG | 900-930 | 1000-60000 | De-ionized water | 65 |

| RIK09120K-40TDG | 900-930 | 2000-120000 | De-ionized water | 57 |

RFHIC’s GaN solid-state microwave generators leverage GaN solid-state technology, ensuring high performance and reliability for sterilization equipment and waste management solutions.

Advantages of RFHIC’s GaN Solid-State Technology

1. Higher Power Density: RFHIC’s GaN amplifiers offer higher power outputs compared to traditional silicon-based devices. This makes them ideal for high-demand sterilization applications where power and efficiency are critical.

2. Greater Efficiency: GaN devices are highly efficient, consuming less energy while providing the same or greater output. This results in lower operational costs, which is crucial for healthcare facilities with budget constraints.

3. Compact Design: GaN technology allows for more compact systems, saving space in medical facilities where equipment footprint matters.

4. Longer Lifespan: GaN devices have greater thermal stability and durability, resulting in longer operational lifetimes and less maintenance, reducing the total cost of ownership.

5. Versatility: RFHIC’s GaN technology can be used in both sterilization and waste treatment systems, providing healthcare facilities with a flexible and scalable solution.

Market Growth of Microwave Sterilization Equipment

The market for microwave sterilization equipment is expected to grow significantly in the coming years. The rise in hospital-acquired infections (HAIs), the need for safer waste disposal methods, and the increasing use of disposable medical devices have all contributed to the demand for advanced sterilization technologies. Microwave sterilization, with its advantages in speed, energy efficiency, and environmental friendliness, is poised to capture a significant portion of this expanding market.

In addition, microwave sterilization systems have proven effective in developing countries, where traditional waste disposal methods, such as incineration, are often not feasible due to infrastructure limitations or environmental concerns. The ability to sterilize biohazardous waste on-site using decentralized microwave systems offers a viable solution for countries facing healthcare challenges.

Summary

Microwave heating technologies are rapidly transforming the field of medical sterilization and waste management. RFHIC’s GaN-based microwave generators provide superior power, efficiency, and flexibility for sterilizing medical instruments and inactivating biohazardous waste. As the global demand for effective, energy-efficient sterilization solutions continues to grow, RFHIC’s innovative GaN solid-state microwave solutions are well positioned to be integrated into the market, offering healthcare facilities a reliable, cost-effective, and environmentally friendly solution for both medical sterilization and waste management applications.

If you would like to learn more about how RFHIC’s GaN solid-state microwave technology enhances microwave sterilization, please fill out the form below.