Wireless Infrastructure

While hydrogen is a promising energy source, producing it through traditional methods has often been an unsustainable process. According to Wood Mackenzie, more than 99.6% of current hydrogen production comes from natural gas reforming and coal gasification, both of which emit high levels of CO₂. This poses a significant challenge for industries looking to decarbonize and transition to cleaner fuels. To accelerate the shift away from these carbon-intensive methods, the world needs a more cost-effective and environmentally friendly hydrogen production solution.

There is growing momentum behind the adoption of low-carbon hydrogen. In fact, Bloomberg NEF estimates that subsidies for low-carbon hydrogen technologies have surpassed $280 billion worldwide in the past two years. This reflects the urgent need for scalable, clean alternatives to traditional hydrogen production - technologies like microwave-assisted methane pyrolysis are emerging as viable solutions.

As industries continue to decarbonize, the use of microwave-assisted processes in hydrogen production and other highly valuable chemicals are becoming an attractive alternative.

Current Hydrogen Production Methods

Hydrogen is seen as a key player in decarbonizing industries such as chemical production, transportation, and steel manufacturing. However, the production of hydrogen itself is often energy-intensive and relies heavily on methods that produce significant CO₂ emissions. Current solutions within the market are:

2. Electrolysis: Electrolysis uses renewable electricity to split water into hydrogen and oxygen, offering a zero-emission hydrogen production method if powered entirely by renewable energy. However, it is capital- and energy-intensive, requiring large-scale renewable power infrastructure. Additionally, electrolysis has significant operational costs, and the renewable power demand can represent over half of a project’s lifetime costs.

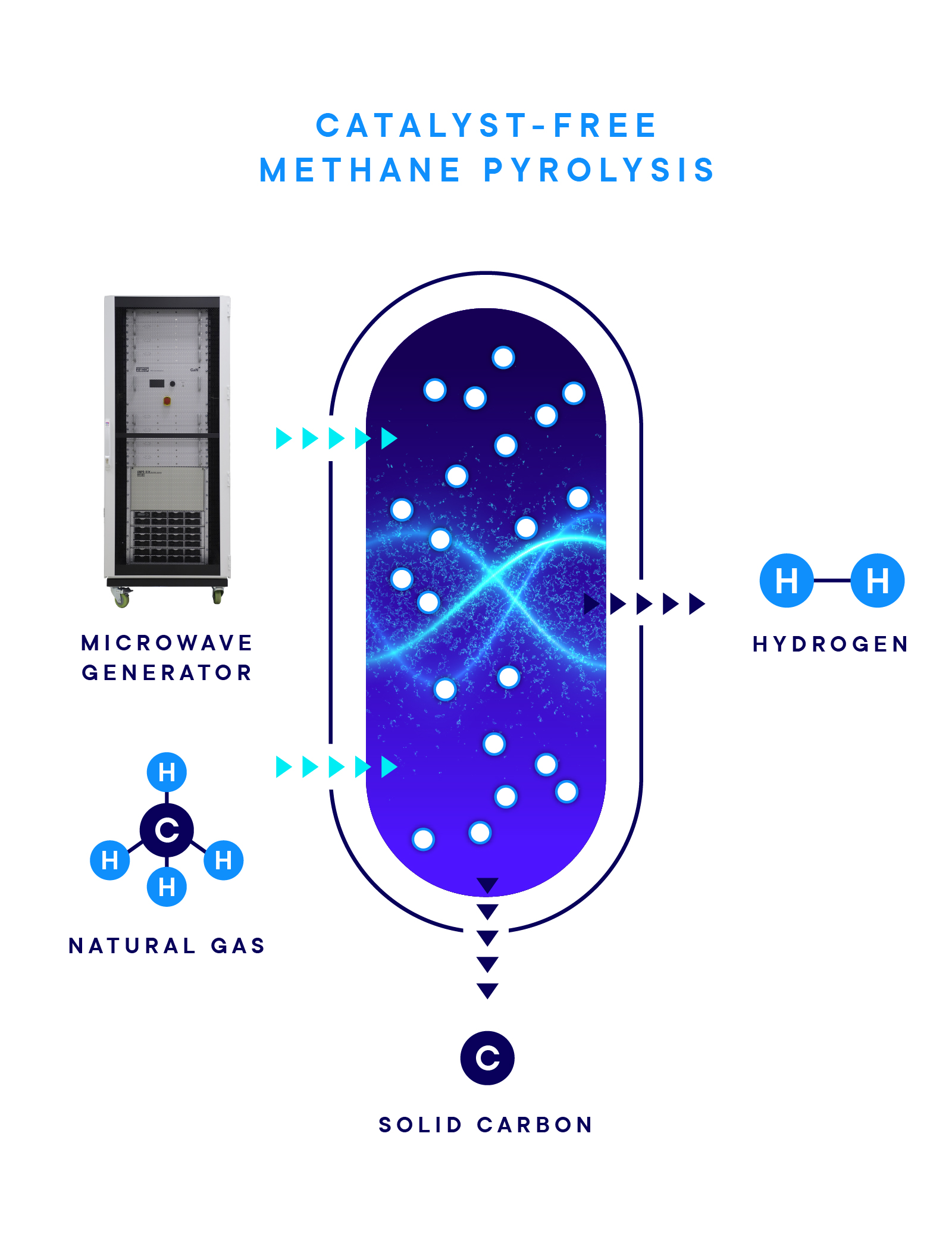

3. Methane Pyrolysis: Methane pyrolysis is gaining recognition as a cleaner, more energy-efficient alternative. It involves breaking down methane into hydrogen and solid carbon without producing CO₂ When powered by renewable energy, methane pyrolysis can achieve net-zero or even net-negative emissions, making it an attractive option for the future.

Microwave-Assisted Methane Pyrolysis

Methane pyrolysis typically requires a significant amount of heat to break down methane molecules into hydrogen and carbon. Microwave technology has introduced a groundbreaking alternative to conventional heating methods, offering several advantages:

Non-Combustible Process: Unlike combustion-based technologies that produce CO₂ and other pollutants, microwave-assisted methane pyrolysis generates heat through microwave energy, ensuring that no CO₂ is emitted. This process leads to the production of hydrogen and solid carbon, eliminating the need for CO₂ capture infrastructure.

This process uses microwaves to heat carbon particles in a reactor, causing them to absorb energy and decompose methane efficiently. By focusing heat where it’s needed and avoiding the use of oxygen or water, this method requires 80% less electricity per kilogram of hydrogen compared to electrolysis.

Microwave-assisted methane pyrolysis processes do not rely on water, CO₂ storage, or CO₂ pipelines, which could potentially lower the capital investment needed for establishing hydrogen production plants. This approach may offer a more cost-effective alternative to traditional methods by minimizing the infrastructure typically required for handling emissions.

The Future of Microwave Technology in Hydrogen Production

The adoption of microwave-assisted methane pyrolysis is expected to grow as industries seek cleaner and more efficient hydrogen production methods. When combined with RFHIC’s GaN solid-state microwave generators, this technology may offer a scalable and cost-effective solution that addresses some of the environmental and logistical challenges traditionally faced in hydrogen production technologies.

You can explore all of our high-powered GaN solid-state microwave generator solutions at our website. RF Energy Catalogue

Below are some of our COTS (commercial off-the-shelf) high-powered GaN solid-state microwave generator solutions designed for hydrogen production and methane pyrolysis applications.

Click to View in Fullscreen

Microwave technology’s capacity to produce hydrogen without direct CO₂ emissions, along with its efficiency and flexibility, could position it as an important tool for reducing carbon emissions in carbon-intensive sectors. As the demand for hydrogen rises, microwave-assisted methane pyrolysis has the potential to emerge as a viable alternative to meet growing energy needs while helping to minimize environmental impact

If you are a hydrogen or methane pyrolysis system manufacturer interested in exploring microwave-assisted technologies, or looking for a reliable microwave source manufacturer, we invite you to contact us for more information. RFHIC’s advanced GaN solid-state microwave generators offer scalable and energy-efficient solutions that can be customized to meet your unique system requirements. Please contact us by filling out the form below.

In the meantime, you can check out these relevant articles related to waste gasification and hydrogen production below:

\References

A.H. (2024). Unlocking Low-Cost Clean Hydrogen for Carbon-Intensive Sectors. (Document ID: file-SfrUA4OzO3cTDhwOnmjoAToj).

M.G. (2024). Atmospheric Microwave Plasma Technology: High-Temperature and Power-to-X Applications. (Document ID: file-SfrUA4OzO3cTDhwOnmjoAToj).

T.M. (2024). Clean Gas Solutions for a Sustainable Future. (Document ID: file-SfrUA4OzO3cTDhwOnmjoAToj).

P.T.D. (2024). The Role of Plasma Technology and Deposition Techniques in Semiconductor Manufacturing. (Document ID: file-krErazqhgGD0dCvuLOYK6Irp).