Wireless Infrastructure

Material processing, particularly sintering, is a key component in the production of high-performance ceramics, composites, and metals. Traditional methods of processing rely on convection or radiation heating, where energy transfer is indirect and often results in inefficient heating and longer processing times. In recent years, microwave technology has emerged as a superior alternative for processing a wide range of materials, offering distinct advantages such as reduced energy consumption, faster processing times, and improved product quality. This article explores the benefits of microwave heating in material processing and sintering, highlights the market potential, and presents RFHIC's GaN solid-state microwave generators as an optimal solution for industrial applications.

Advantages of Microwave Technology in Material Processing

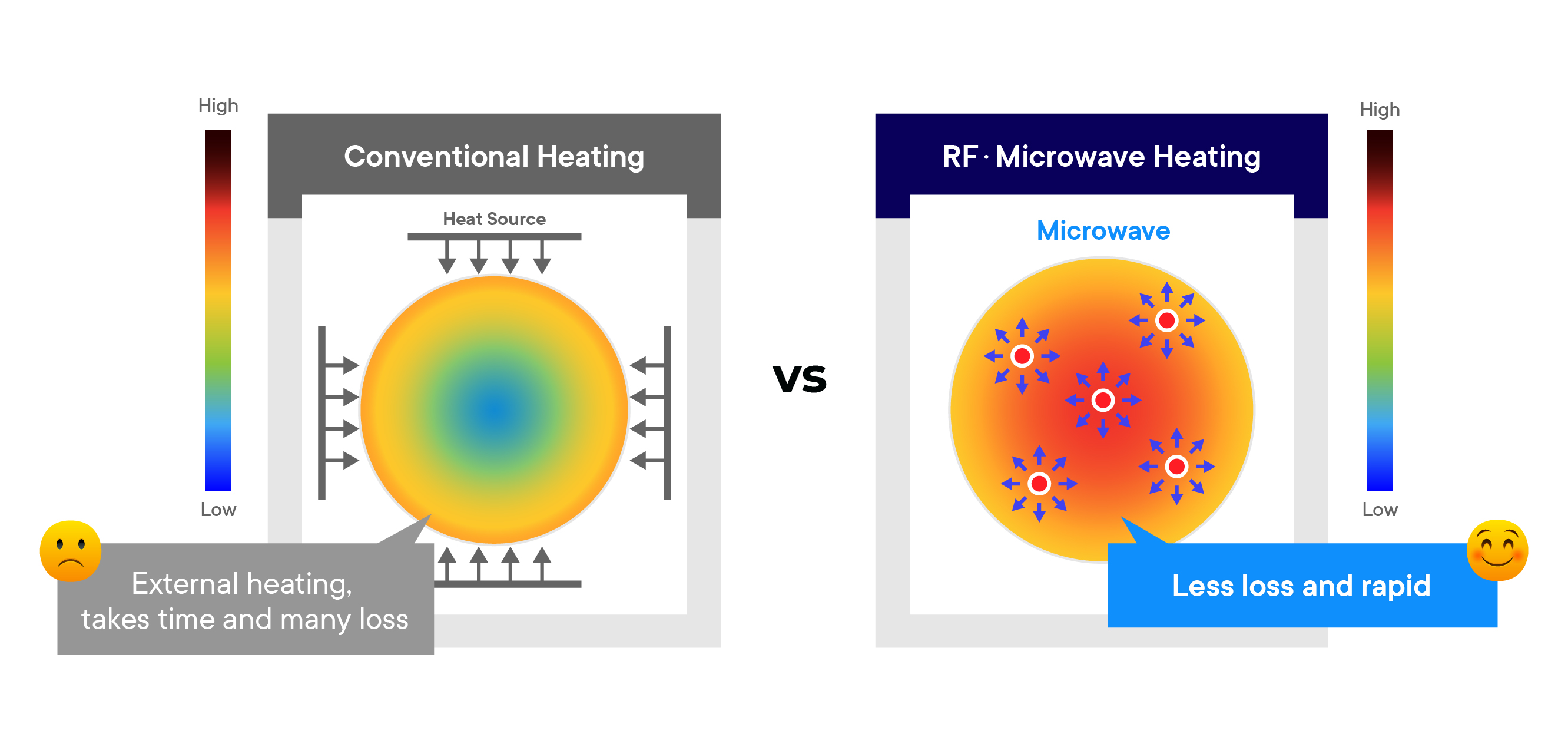

Microwave heating fundamentally differs from conventional methods in the way energy is transferred to materials. Unlike traditional heating, which relies on conduction and convection, microwave heating directly interacts with the material at the molecular level. This direct interaction allows for volumetric heating, wherein energy is absorbed uniformly throughout the material, resulting in faster and more efficient processing. Studies have shown that microwave heating can significantly reduce processing temperatures and times while improving the mechanical properties of the material being processed【7†source】【8†source】.

Sintering with Microwave Technology

Sintering is the process of compacting and forming materials through heat without liquefying them, has traditionally been energy-intensive and time-consuming. However, with the use of microwave technology – microwave sintering, offers a more energy-efficient and time-saving alternative.

Research has demonstrated that microwave sintering not only accelerates the densification process but also enhances the microstructure of the materials, leading to finer grains and improved mechanical properties. For instance, ceramics such as alumina and zirconia, which typically require high sintering temperatures and long hold times in conventional processes, can be sintered at significantly lower temperatures and in much shorter times using microwave technology【9†source】. This reduction in temperature also helps preserve the material's microstructure, resulting in products with superior qualities.

Comparing Microwave Heating to Conventional Methods

Conventional heating methods, such as furnace heating, rely on external sources to transfer heat into the material. This process is slow, energy-intensive, and often leads to uneven heating, which can negatively affect the quality of the final product.

In contrast, microwave heating provides rapid, uniform heating throughout the material, reducing the risk of thermal gradients and non-uniform properties【8†source】. Additionally, microwave processing offers significant energy savings by targeting the material directly, rather than heating the entire furnace structure.

Microwave heating also presents environmental benefits, as it reduces energy consumption and CO2 emissions. This is particularly important in industries such as steel production and tire recycling, where conventional methods are not only inefficient but also environmentally damaging. Microwave technology enables cleaner, more sustainable processing methods【8†source】.

Market Size and Opportunities

The global market for microwave materials processing is growing, driven by the need for more energy-efficient and sustainable production methods. The demand for advanced ceramics, nanomaterials, and metal composites in industries such as aerospace, automotive, and electronics is expected to fuel the adoption of microwave processing technologies. According to recent market research, the global microwave-assisted synthesis market is projected to reach $3.5 billion by 2027, with significant growth potential in material science and industrial applications【7†source】.

There is a rising demand for efficient processing techniques in industries such as pharmaceuticals, advanced manufacturing, and environmental remediation, which positions microwave technology as a promising solution for future industrial needs. As industries continue to prioritize sustainability, microwave processing offers a pathway to reduce energy consumption and improve product quality, creating ample opportunities for growth and innovation.

RFHIC's GaN Solid-State Microwave Technology

RFHIC's GaN (gallium nitride) solid-state microwave generators represent a significant advancement in microwave technology, which can be used for material processing technology. Compared to traditional conventional heating methods, RFHIC’s GaN solid-state technology offers higher efficiency, greater power control, and enhanced reliability unlike imagined before. The advantages of GaN solid-state technology in microwave processing are numerous:

1. Higher Efficiency: GaN devices convert more electrical power into microwave energy, reducing energy consumption and operating costs. This makes them particularly suitable for large-scale industrial processes where energy efficiency is a priority.

2. Precise Power Control: RFHIC's GaN solid-state amplifiers allow for precise control over microwave power and frequency, enabling fine-tuning of the heating process. This results in improved product quality and reduced production times【7†source】.

3. Scalability: GaN technology is highly scalable, making it suitable for applications ranging from small-scale laboratory research to large-scale industrial production. Its flexibility in power levels and frequency ranges expands the possibilities for microwave-assisted material processing【8†source】.

4. Reliability and Longevity: With lifespans of up to 50,000 hours, RFHIC's GaN amplifiers are designed for continuous operation in demanding industrial environments. This ensures minimal downtime and maintenance, improving overall productivity.

Click to View in Fullscreen

Off-the-Shelf Microwave Generators

RFHIC offers a range of off-the-shelf microwave generators suitable for material processing and sintering applications. These systems are designed to meet the needs of various industries, providing flexible and scalable solutions for efficient and sustainable material processing. Some of the key products include:

These systems are equipped with advanced features such as precise frequency tuning, robust construction, and extended lifespans, making them an excellent choice for industries looking to enhance their material processing capabilities.

Conclusion

Microwave technology is revolutionizing material processing and sintering by providing faster, more efficient, and environmentally friendly alternatives to traditional methods. As industries continue to seek ways to improve productivity while reducing energy consumption, the adoption of microwave processing technologies is expected to grow.

RFHIC's GaN solid-state microwave generators offer a superior solution for a wide range of industrial applications, delivering unmatched efficiency, control, and reliability. By embracing microwave technology, industries can enhance their production processes, improve product quality, and contribute to a more sustainable future.

For more information on RFHIC's GaN solid-state microwave solutions and their applications in material processing, please fill out the form below.

References:

[1] D.E. Clark, D.C. Folz, J.K. West, "Microwave Processing of Materials: Part I", Materials Research Society Bulletin, 1993.

[2] Y.V. Bykov, K.I. Rybakov, V.E. Semenov, "High-temperature microwave processing of materials", Journal of Physics D: Applied Physics, 2001.

[3] J. Wang et al., "Evidence for the microwave effect during hybrid sintering", Journal of the American Ceramic Society, 2006.

[4] R. Roy et al., "Definitive experimental evidence for microwave effects: radically enhanced reaction rates", Materials Research Innovations, 2002.

[5] Z.J. Huang et al., "Improving sinterability of ceramics using hybrid microwave heating", Journal of Materials Processing Technology, 2009.

[6] D.K. Agrawal, "Microwave processing of ceramics", Current Opinion in Solid State and Materials Science, 1998.

[7] J. Cheng et al., "Microwave reactive sintering to fully transparent aluminum oxynitride (ALON) ceramics", Journal of Materials Science Letters, 2001.

[8] K.H. Brosnan, G.L. Messing, D.K. Agrawal, "Microwave Sintering of Alumina at 2.45 GHz", Journal of the American Ceramic Society, 2003.

[9] R.M. Anklekar, D.K. Agrawal, R. Roy, "Microwave sintering and mechanical properties of PM copper steel", Powder Metallurgy, 2001.

[10] "Microwave Heating Market", Allied Market Research, 2022.

[11] "Industrial Microwave Heating Equipment Market", Global Market Insights, 2021.