Wireless Infrastructure

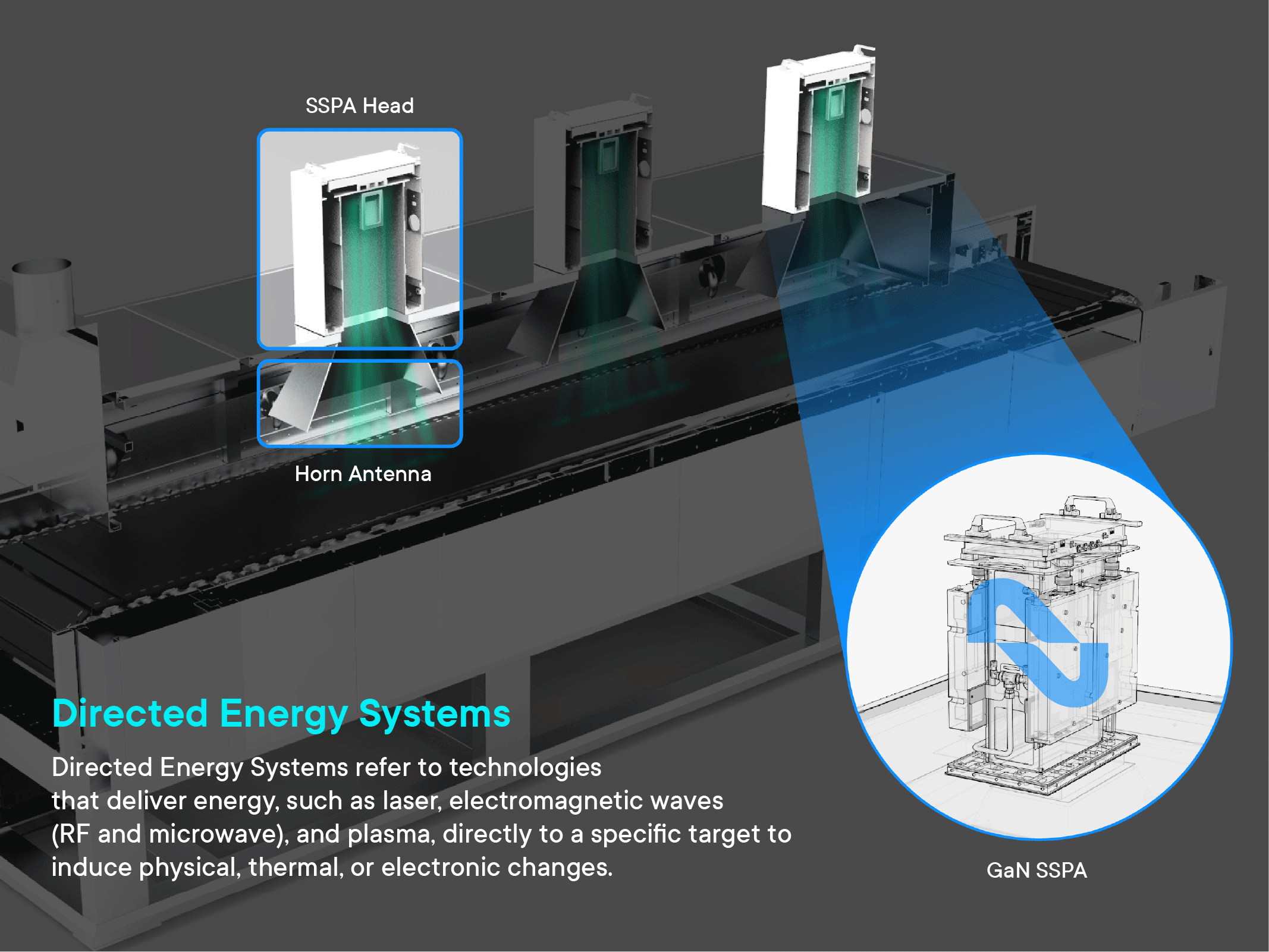

What are Directed Energy Systems?

Directed Energy Systems refer to technologies that deliver energy, such as laser, electromagnetic waves (RF and microwave), and plasma, directly to a specific target to induce physical, thermal, or electronic changes. These systems are utilized across various industries and are highly valued for their ability to transfer energy in a non-contact manner.

In industrial applications, directed energy systems are widely used for rapid heating, drying, and precision material processing. Unlike traditional heating methods that rely on conduction or convection, these systems deliver energy directly into materials, allowing for faster and more precise processes. This ability to provide efficient, highly precise, and contamination-free heating makes them essential in modern manufacturing environments.

GaN Solid-State MW System vs Electronic Heating System

| Category | GaN Solid-State MW System | Electronic Heating System |

| Energy Efficiency |

High efficiency (focused heating with less power) |

Medium efficiency (higher power consumption) |

| Precision and Control |

High precision (selective and uniform heating) |

Lower precision (Potential for uneven heating) |

| Maintenance and Lifespan | Low maintenance (Long lifespan) |

Frequent maintenance, Heating element replacement required |

| Installation Cost | Higher initial installation cost | Lower initial installation cost |

| Space Efficiency | Compact, space-efficient | May require more space |

| Applications | Suitable for food, textile, rubber, drying, preheating, fast processes | Suitable for small industries, simple heating processes |

| Temperature Control | Fast and accurate temperature control | Slower temperature change, potential for uneven heating |

| Long-term Cost Savings | Higher initial cost, long-term cost savings | Lower initial cost, but higher maintenance and energy costs over time |

| Technical Features | GaN-based, superior frequency and output control | Heat generated through resistance, simpler structure |

Advantages of Microwave Heating and Drying in Industrial Applications

Microwave energy uses electromagnetic waves to simultaneously heat both the inside and outside of materials, proving its effectiveness and efficiency in a range of industrial processes. Key advantages include:

1. Fast Heating and Drying

Microwave technology significantly reduces heating times compared to conventional methods. The Journal of Food Engineering reports that microwave drying can reduce the drying time of food items such as fruits, vegetables, and meat by up to 50%. This is because microwaves heat both the interior and exterior of the material at the same time.

2. High Energy Efficiency

Microwaves deliver concentrated energy, resulting in higher energy efficiency. According to the IEEE Transactions on Microwave Theory and Techniques, microwave heating systems are up to 30% more energy-efficient than traditional low-frequency methods, leading to significant cost savings.

3. Uniform Heat Distribution

Microwave energy uniformly heats materials by causing molecules inside the material to vibrate evenly. The Journal of Industrial Microwave Applications highlights that microwave systems provide uniform heating, particularly beneficial in food and textile processing, where product quality is critical.

4. Non-contact Heating

Microwave systems heat materials without direct contact, making them ideal for hygienic processes in industries such as pharmaceuticals and food. The International Journal of Food Science and Technology notes that non-contact microwave drying preserves the nutritional value of food while ensuring safety.

Industrial Applications of RFHIC’s GaN Solid-State Microwave Generators

RFHIC’s GaN solid-state microwave generators play a pivotal role in enhancing energy delivery and process efficiency across various industries. Below are some key industrial applications:

1. Food Processing Industry

2. Textile and Polymer Processing

3. Rubber Industry

Why Choose RFHIC's GaN Solid-State Microwave Generators?

RFHIC has revolutionized industrial microwave systems with its GaN-based solid-state microwave generators. GaN technology offers superior performance, longer lifespan, and smaller equipment sizes compared to traditional vacuum tube systems.

1. High Power Efficiency

GaN-based solid-state technology is up to 50% more power-efficient than vacuum tube systems, according to the Journal of Applied Physics. This reduction in power consumption leads to significant energy savings, especially in large-scale industrial operations.

2. Long Lifespan and Reliability

GaN technology offers up to 10 times the lifespan of vacuum tube systems. IEEE Power Electronics Magazine reports that GaN-based solid-state systems provide higher reliability and reduce maintenance costs, minimizing production downtime.

3. Miniaturization and Space-saving

GaN-based systems are more compact, making installation and operation easier. Their small footprint is a significant advantage in industrial environments where space is limited.

4. Instant Output Control and Precision Heating

GaN solid-state technology allows for instant power adjustment and precise heating control, making it ideal for processing temperature-sensitive products. The Journal of Microwave Power and Electromagnetic Energy reports that GaN-based systems excel in applications requiring precise temperature management.

5. Environmental Friendliness

GaN technology reduces carbon emissions through lower energy usage. The Energy Efficiency Journal states that GaN-based industrial heating systems reduce carbon emissions by over 30%, contributing to more sustainable industrial operations.

RFHIC’s Recommended GaN Solid-State Microwave Generators

RFHIC offers GaN-based solid-state microwave generators suitable for various industrial heating and drying processes. The most recommended products are as follows:

| Product | Product Info | Product Image |

|

RIM25100-20G |

100W, 2400~2500MHz |

|

| RIM25200-20G | 200W, 2400~2500MHz |

|

RWP0809300-55 |

300W, 2400~2500MHz |  |

| RIM251K6-20 | 1.6kW, 2400~2500MHz |

|

| RIU093K0-40TG | 3kW, 900~930MHz |

|

| RIK0960K0-40TDG | 60kW, 900~930MHz |  |

Conclusion

GaN-based solid-state microwave generators offer a revolutionary advancement in industrial heating and drying systems, significantly enhancing performance and efficiency. With superior energy efficiency, precise control, and longer lifespans, these systems boost productivity while cutting costs and supporting environmental sustainability. RFHIC’s GaN solid-state microwave generators represent the best choice to replace traditional vacuum tube systems, strengthening businesses' competitiveness while enabling more efficient and sustainable industrial operations.

If you are a business involved in related industries or are interested in RFHIC’s GaN solid-state solutions for particle accelerators, we encourage you to fill out the form below for further inquiries.